V BELT LITERATURE

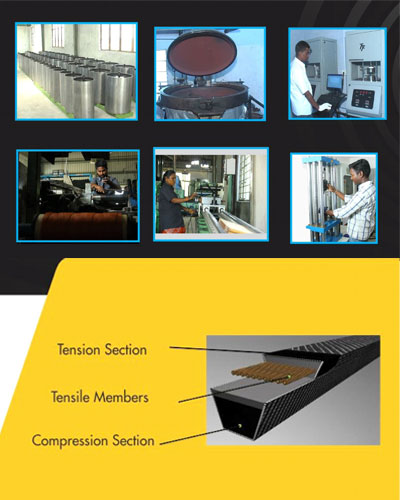

Belt drives are called flexible machine elements. Flexible machine elements are used for a large number of industrial applications, viz., conveying systems, transmission of power, etc.

Belt drives are called flexible machine elements. Flexible machine elements are used for a large number of industrial applications, viz., conveying systems, transmission of power, etc.

Flexible machine elements has got an inherent advantage that, it can absorb a good amount of shock and vibration. It can take care of some degree of misalignment between the driven and the driver machines and long distance power transmission, in comparison to other transmission systems, is possible.

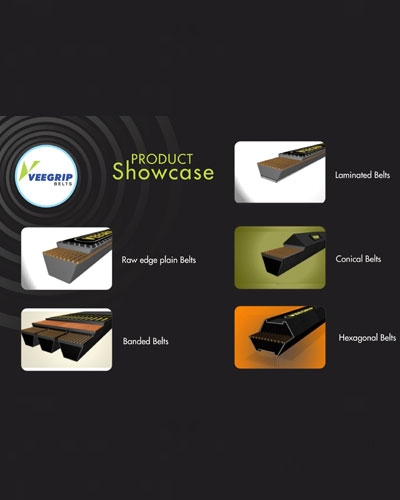

For the entire above reasons flexible machine elements are widely used in industrial application.V-belts are the workhorse within an industry. They are available in a wide variety of standard sizes, for transmitting any amount of load power.

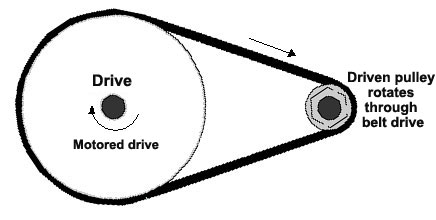

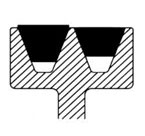

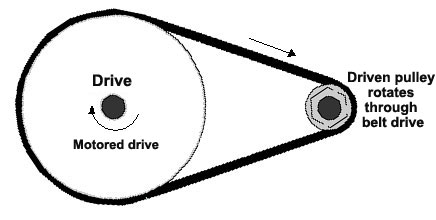

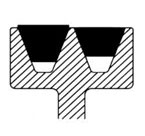

The belt drives primarily operate on the friction principle (Principle of wedging). i.e. the friction between the belt and the pulley is responsible for transmitting power from one pulley to the other. In other words the driving pulley will give a motion to the belt and the motion of the belt will be transmitted to the driven pulley.

Belt drives may be used for any type of power transmission purposes such as Machinery such as agricultural equipments, Automobiles, Home appliances, Process industries like steel plants, pharmaceutical industries, sugar and paper mills, textile looms, rice mills, etc…

Under proper storage conditions, VEEGRIP belts can be used for many years without deterioration of quality and service life. The following guidelines may be used:

Belt drives are called flexible machine elements. Flexible machine elements are used for a large number of industrial applications, viz., conveying systems, transmission of power, etc.

Flexible machine elements has got an inherent advantage that, it can absorb a good amount of shock and vibration. It can take care of some degree of misalignment between the driven and the driver machines and long distance power transmission, in comparison to other transmission systems, is possible.

For the entire above reasons flexible machine elements are widely used in industrial application.V-belts are the workhorse within an industry. They are available in a wide variety of standard sizes, for transmitting any amount of load power.

The belt drives primarily operate on the friction principle (Principle of wedging). i.e. the friction between the belt and the pulley is responsible for transmitting power from one pulley to the other. In other words the driving pulley will give a motion to the belt and the motion of the belt will be transmitted to the driven pulley.

Belt drives may be used for any type of power transmission purposes such as Machinery such as agricultural equipments, Automobiles, Home appliances, Process industries like steel plants, pharmaceutical industries, sugar and paper mills, textile looms, rice mills, etc…

Under proper storage conditions, VEEGRIP belts can be used for many years without deterioration of quality and service life. The following guidelines may be used: